The Winton Vs. Arbour

2-6-6-6 Construction

Page 5

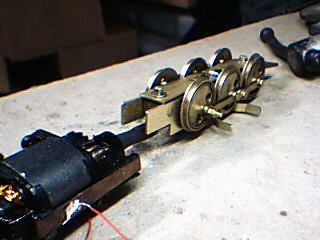

Putting together the Winton Siderod assemblies.

I will first do the rear drivers.

A nut driver will be very handy here.

Holding the frame in a vise to keep it steady,

first pin is a breeze.

Next pin a little trickier, I had to hold the

pin in the needlenose pliers while turning slightly,

then chased it in with the nut driver, while making sure

the washer underneath stays in place.

Next pin was trickier, I cheated using the goo

container as a sticky holder which allowed me to place the

pin well, but got some goo on the parts, but its not a place where

rotation is a hazard, so it worked...

but cannot do that again.

A little bit of goo on the nut driver allowed me to

hold the pin steady while I placed it on.

Other side went fairly well.

With the gear mounts off, I could check for free wheeling.

They rolled reasonably smooth, but I detected

a litle binding, the wheels are slightly off perfect quartering.

If they are all off the same, if may not affect operation.

Wear in and lubrication should help this.

After a while, I found one of the middle bearings

was rough to turn, I believe run in is the only solution.

After some part searching and finagling,

I got the worm gear on, which was a tougher going,

it has a tiny screw with a threaded hole in the shaft.

I finagled some Athearn drive parts for test running.

Hey, a flywheel already!!!

Now I find I have the gear on backwards.

Tough.

Whatacrazymessofpartsalready.

You can see the problem I have in inserting the tiny

screw thru the shaft, the gear has a hole, and the shaft has

a threaded hole. I had it in it once, but it looks like I need to be able

to

remove it at a moments notice if need be in this construction.

I recall there are bolts with unthreaded leads, well,

this screw will get the treatment.

One filing job later...

Yesh!!!

I actually had it backwards again but the switch was

speedier this time. I gave the worm gear and driver

a workout after lubing, and it ran AOK in one direction,

but jammed the other way, I expected that due to

loose bearings, which I will spot solder later.

After a while of spinning the middle driver,

I removed it and I could freely spin the bearings.

The screws were slightly loose, tightening them tightened

the pressure on the driver which forced more wear.

Once reasonably free, I put the other drivers on

and spun them, slowly they free some.

It is still not perfect, there is some binding, but more run tests will be

done.

I will not put the linkage valve gear on at this time as it is more

cosmetic. I will now persue buying a DC-91 or replacement

motor. The gears have proven their rough and tough

design to get the drivers worn in.

The front set of drivers already move freely so

there is no issue there.